Firing up the Next Generation

Young potters in the ancient heartlands of ceramic industry are carrying forward the craft of celadon-glazed porcelain production, Deng Zhangyu and Ma Zhenhuan report.

Editor's note: There are 43 items inscribed on UNESCO's Intangible Cultural Heritage lists that not only bear witness to the past glories of Chinese civilization, but also continue to shine today. China Daily looks at the protection and inheritance of some of these cultural legacies. In this installment, we lift the lid on the history of Chinese pottery, from the millennia-old formulas used to create celadon glazes, to the artisans modernizing the ancient craft today.

On an early August morning, craftsman Zhang Xi drove his car quickly through the twists and turns of a mountain road in Longquan, Zhejiang province, hoping to reach his destination — a century-old kiln — as soon as possible, where hundreds of pieces of pottery that had been given their final celadon glaze were finally ready.

The 51-year-old craftsman has used the old kiln, which is nestled on a mountain near Xitou village, for many years. Every time he removes his creations from the kiln, seeing them in their finished celadon color remains as exciting and nerve jangling as ever.

"It's like opening blind boxes. The same formula of glaze applied to different vases can look totally different on each one," says Zhang.

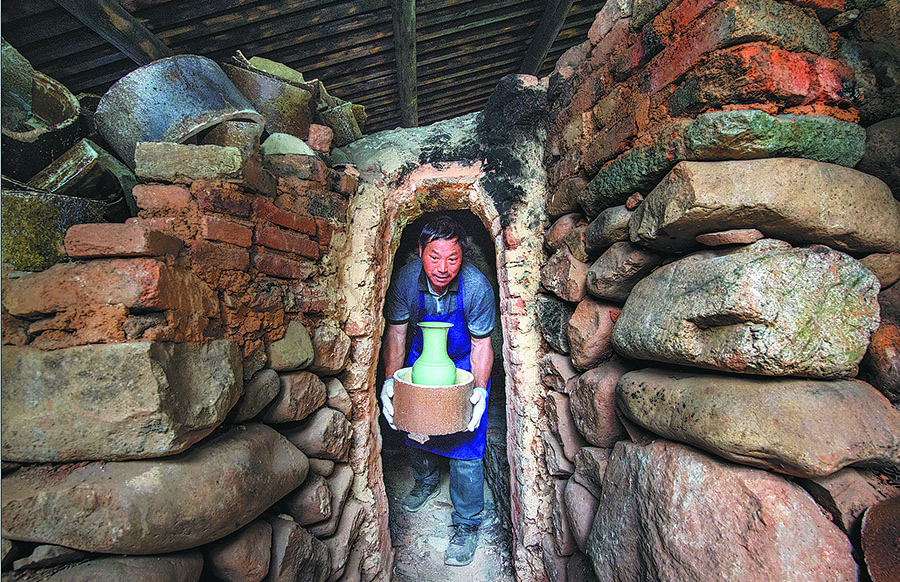

Potters work at a kiln in Xitou village in Longquan, Zhejiang province. [Photo provided to China Daily]

Their colors usually fall in the spectrum between lavender gray and plum green. Sometimes though, they turn out brown or yellow. All these colors depend on temperature changes during the two-day firing — a process described by local craftsmen as "a song of clay and fire".

The traditional firing techniques of Longquan celadon pottery, which dates back further than 1,600 years, was included on UNESCO's Intangible Cultural Heritage of Humanity List in 2009.

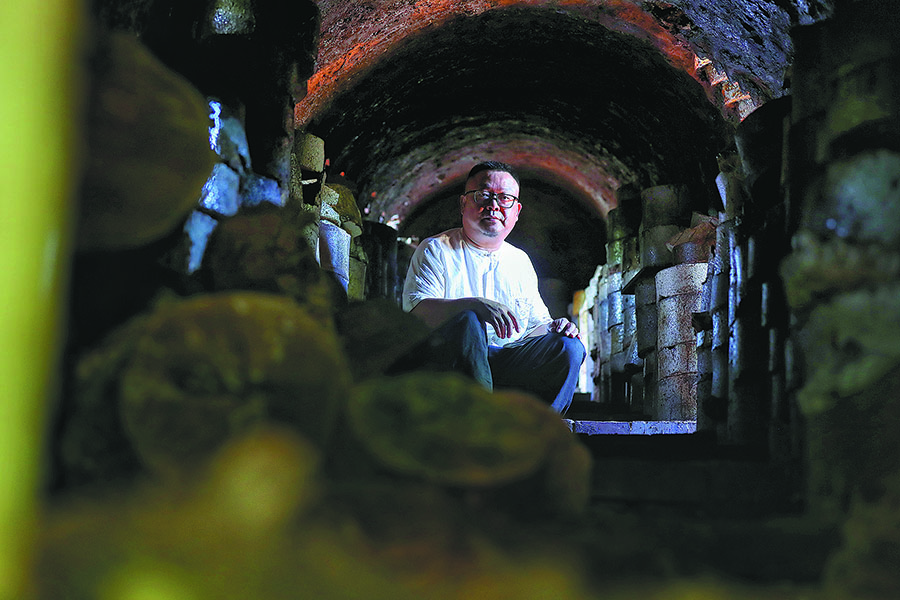

[Photo by Jiang Dong/China Daily]

An experienced craftsman, Zhang began learning about making celadon-glazed pottery in a wood-fired kiln from his grandfather at the age of 18. The craft has been passed down through his family since the 18th century.

Many families in the village, like Zhang's, made their living from the traditional craft for centuries, but with the introduction of gas kilns in 2000, a technology that allows and ensures exact temperature control to produce porcelain with a high-quality glaze, use of traditional wood-burning kilns began to disappear.

"Gas or electrical kilns can ensure the quality of the celadon glaze. Craftsmen can predict what they get from modern kilns, as long as they set the right temperature. However, traditional kilns can offer unexpected surprises, which enamors makers and lovers of the craft," says Zhang, walking alongside the kiln, which is made of brick and clay and is more than 20 meters long.

He checks the temperature of the cooling kiln by touching the bricks, and is able to judge when it's the right time to remove the porcelain treasures inside.

The long kiln, shaped like a snake, can house dozens of vases or hundreds of tea cups. It takes 5,000 kilograms of wood and 12 potters to keep it firing for two days — a high cost in "both time and energy".

Celadon master artisan Zhang Xi in Longquan. [Photo by Jiang Dong/China Daily]

"Every brick kiln has its own personality. This one is very mild and tender, and the color of green it produces is light," Zhang says.

He points to another one standing in front of the village, which in his words is "fierce" and its products are heavy in gloss. A good firing needs half a year of preparation.

After many firings, a craftsman knows the kiln inside out, and learns how to control the precise temperature by watching the color of the flame, or by using a piece of clay as a measure. The heat can reach as high as 1,310 C.

No matter it's a brick kiln or a modern one, the craftsman's aim is to pursue a glaze of exquisite beauty, with their own unique input.

"Just like a chef, we have our own formulas to produce different shades of green, a color similar to jade," says Zhang, adding that they can expertly identify the various shades of green by eye.

To produce Longquan celadon pottery, dozens of steps are needed before firing, such as carving patterns, sticking together different parts, glazing and making tiny adjustments. [Photo by Jiang Dong/China Daily]

Green attraction

Since the porcelain was produced in Longquan during the Three Kingdoms period (220-280), it has been widely used, becoming a household staple across the nation and also adored by royal families both at home and abroad.

Within the city of Longquan, more than 500 sites that used to be kiln clusters were discovered by archaeologists, a telling testimony of the prosperity of Longquan's celadon-glazed pottery industry.

The production of Longquan celadon reached its peak during the Southern Song Dynasty (1127-1279). Many thousands of porcelain items bearing the famous green glaze were shipped to Southeast Asia, Europe and East Africa.

The name, celadon, is derived from a French novel L' Astree. The name of the story's protagonist is the shepherd Celadon, who wears a green cloak. His look became chic in 17th century Paris. At the time, the Longquan porcelain, which shared a similar color to the fictional hero's cloak, was popular among the upper class in France.

"The simple shape and jade-like color of the porcelain is a vivid demonstration of Chinese culture and aesthetics," says Liu Ying, director of the Celadon Museum in Longquan.

To produce Longquan celadon pottery, dozens of steps are needed before firing, such as carving patterns, sticking together different parts, glazing and making tiny adjustments. [Photo by Jiang Dong/China Daily]

Celadon is like Chinese people's personality — it's subtle, gentle, quiet and reserved. Because of its color and glossy finish, it's also called "artificial jade", reflecting people's love of the precious stone, which bears the virtues that Chinese people pursue and cherish still, says Liu.

"Celadon is also a color from nature. In traditional culture, Chinese people always promote a harmonious way to coexist with nature," adds Liu.

In the eyes of budding craftsman Yang Leping, all things related to celadon pottery are about nature. The 72 processes needed to produce Longquan celadon-glazed pottery are all related to elements found in nature, including fire, wood, clay and water.

Yang says the name of two typical green varieties are also from nature. Lavender gray, or tianqing in Chinese, means the color of the sky after rain. The plum green, obviously, refers to the fruit, just as it's about to ripen.

The 27-year-old set up his own studio in 2016 to seek the exquisite beauty of green glaze. Every time he feels any doubt, he will go back to Dayao village in Longquan, his birthplace and now an archaeological park. It is the site where many millennium-old kilns were found.

"When I was a kid, I enjoyed collecting pieces of celadon pottery found at my family's farmland. My grandfather hoed the weed, and lots of fragments of the local porcelain would be unearthed. That was my early introduction of the different shades of green," says Yang.

Yang's inspiration all comes from nature. He loves to explore the mountains around the city of Longquan and walk along rivers and through the villages.

To get a perfect green glaze, Yang has to run the gauntlet of uncertainty throughout the 72 processes — a wrong temperature or bad weather could spell failure.

"I think the persistent pursuit of a perfect hue of green explains why Longquan celadon pottery has enjoyed centuries of popularity," Yang says.

Liu, the celadon pottery museum director, says that its charm lies in the spirit of craftsmanship that has continued for centuries.

To produce Longquan celadon pottery, dozens of steps are needed before firing, such as carving patterns, sticking together different parts, glazing and making tiny adjustments. [Photo by Jiang Dong/China Daily]

Family business

After graduation, Chen Guo went to work in Hangzhou, the capital of Zhejiang province. One year later, she was asked to return home to Longquan by her mother, Chen Shaoqing, an established potter who learned the craft from her mother.

Chen Guo's college major had nothing to do with pottery. However, she is keen to follow her mother and grandmother and continue the craft in their spirit.

"It's like a mission passed down through families," says the young woman.

Since childhood, celadon pottery has been part of her life. Her toys were pieces of ceramic, and she played at the factory where her mother worked.

To produce Longquan celadon pottery, dozens of steps are needed before firing, such as carving patterns, sticking together different parts, glazing and making tiny adjustments. [Photo by Jiang Dong/China Daily]

Products of Chen Shaoqing have long been selected by the nation as diplomatic gifts for foreign guests who visit China. As a daughter and apprentice to her mother, Chen Guo chooses to combine the celadon glaze with modern pottery designs.

Many of Chen Guo's buyers are young people, and she sells her products through online livestreams, while her mother's customers are mostly people in or above middle age who choose to purchase items in more traditional ways.

Many young people like Chen Guo choose to stay in Longquan, where, for generations, glaze formulas and pottery techniques have been handed down within families or through teachers.

Celadon master artisan Xia Houwen in Longquan. [Photo by Jiang Dong/China Daily]

Xia Houhui also learned the craft of making celadon-glazed pottery from his father, Xia Houwen, a national-level inheritor of Longquan celadon. The 88-year-old master made the gifts that were presented to former US president Richard Nixon when he visited China in 1972.

Inheriting the gift from his father, Xia Houhui is now a provincial-level inheritor of Longquan celadon. His father always tells him that the beauty of celadon pottery can last for centuries. "The more you look at it, the more you love it. It's not a love at first sight," says Xia Houwen at the studio he shares with his son.

Xia Houhui agrees with his father that the charm is timeless.

He plans to ask his own son to continue the family's craftsmanship spirit. The youngest Xia is still at college majoring in data and journalism.

"Each generation has their own unique expression of the traditional craft. It helps the craft to live on," says Xia Houhui.

Potters work at a kiln in Xitou village in Longquan, Zhejiang province. [Photo by Jiang Dong/China Daily]